Introcuction of Our study

At Center for Power Source Research for Next Generation Mobility, aiming for zero emissions from automobiles, high efficiency and low emission technology for power trains, measurement and modeling of fuel consumption and emissions during actual driving, and control of power sources and drivers in consideration of V2X(Vehicle to Everything), from basic examination to empirical research.

Chassis dynamometer experiments

In 2014, we introduced a chassis dynamometer for vehicle performance testing at the Next Generation Mobility Center in Chiba University with the support of Ministry of Education, Culture, Sports, Science and Technology's university education and research infrastructure strengthening promotion fund. The chassis dynamometer is a device that puts the wheel of the vehicle on the roller and simulates the actual road to perform dynamic experiments. In order to simulate an actual road, it is possible to give the rollers the same running resistance (load) as the road and perform an experiment in an approximate state. In addition, data on air resistance and vehicle cooling can be obtained by using a vehicle speed proportional blower fan that can simulate up to around 200 km / h. Currently, we are developing research-based models to promote model-based development (MBD) and identifying vehicles using artificial intelligence that has learned test results.

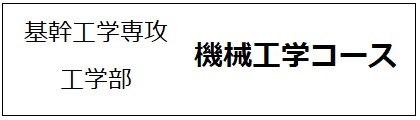

Next-generation natural gas co-generation system

While ultra-high supercharging is required for ultra-high load operation

of gas engines, it also causes combustion instability such as abnormal

combustion and misfire. Therefore, by devising various conditions related

to engine combustion, we have achieved a brake mean effective pressure

(Pme) = 3MPa, which is about 1.5 times the current engine specifications,

while suppressing combustion instability. The realization of ultra-high

load operation also increases thermal efficiency, which can be expected

to improve the power generation efficiency of gas co-generation. In particular,

energy saving effects can be expected by deploying this technology to facilities

with high electricity demand, where it was difficult to obtain sufficient

economic effects due to the introduction of gas co-generation, but the

exhaust heat could not be used up.

We aim to improve the power generation efficiency of gas engines by encouraging

the use of the ultra-high load combustion method adopted in this test single-cylinder

gas engine system for the development of private gas engines in the future.

Actual emission research using PEMS and chassis dynamometer

In 2014, we introduced a chassis dynamometer for vehicle performance testing at the Ministry of Education, Culture, Sports, Science and Technology's university education and research infrastructure strengthening promotion fund. We are conducting performance experiments on excessive conditions, driving modes, and the entire vehicle that are difficult to measure on the engine bench. Recently, there has been a demand for reduction of actual road exhaust gas from automobiles, and research on actual road emissions is becoming more important. Using the chassis dynamometer system and the in-vehicle measurement system (PEMS: Portable Emissions Measurement System), we are investigating and researching actual road exhaust gas during driving based on the actual road speed profile. At the same time, we plan to study the effects of actual road conditions (road surface, slope, temperature, load, etc.) on exhaust gas and fuel efficiency.

※PEMS (Portable Emissions Measurement System): A device that is directly mounted on a vehicle and analyzes regulated automobile exhaust gases (CO, CO2, THC, NOx). It has the feature that the actual situation can be studied most because it is possible to measure while driving on the actual road.

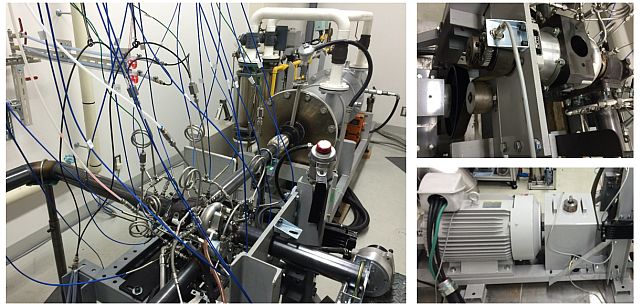

Cylinders variations in turbocharged lean burn engine

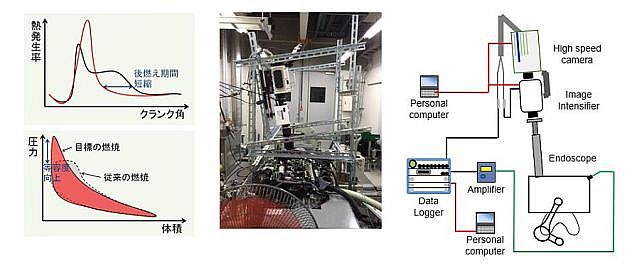

We have a visualization engine equipped with an observation window with optical access to the piston and cylinder, and an end scope attached to the actual engine, the combustion process in the combustion chamber. We are working on high-speed photography and optical measurement to analyze phenomena such as the cause of abnormal combustion in the highly supercharged engine cylinder.

Measurement of cylinder pressure of a highly charged engine

While supercharging downsizing technology has been widely introduced as a fuel efficiency improvement technology, pre-ignition in the low rpm and high load range and subsequent damage to the engine due to super knock have become problems. In order to analyze the damage mechanism of engine parts due to abnormal combustion in the highly supercharged engine cylinder, we are working on measuring the pressure inside the engine cylinder from the side of the cylinder and measuring the pressure vibration inside the engine cylinder and the top land. We also perform detailed phenomenon analysis of pressure vibration by numerical simulation.

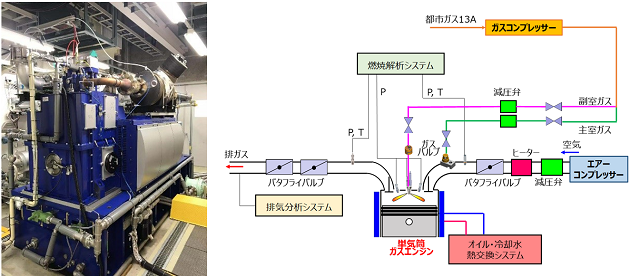

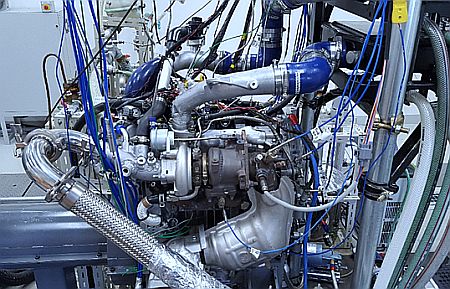

Turbochargers test stand

We have a turbochargers test stand that conducts individual performance tests of turbochargers for the purpose of performance tests of turbocharged systems for automobiles, elucidation of heat and friction loss phenomena, and acquisition of basic data for modeling turbochargers. This stand can "cold test" (with compressed air) and "hot test" (under high temperature and high pressure conditions of up to 1000 ° C ) and also the performance test of the turbocharger is performed under various operating conditions. In addition, by connecting a power meter with a torque meter to the turboshaft via an increase / reduction gear, it is possible to directly measure drive and absorption by the motor and friction torque.

Elucidation of post-burning in diesel engine

This research is working toward the realization of thermal efficiency of 50% as a member of the "diesel combustion team" in the "Strategic Innovation Creation Program (SIP)" led by the Cabinet Office. In diesel engines, it is required to shorten the combustion period and improve the equivalence in order to improve the thermal efficiency. However, regarding the "post-burning" peculiar to diesel combustion, which is a factor that prolongs the combustion period. The influencing factors have not been fully elucidated. In this research, in order to clarify the in-cylinder distribution of the heat generation region and the rate-determining factor of the combustion rate during the afterburning period, we are proceeding with research using visualization inside the actual cylinder and combustion pressure analysis for new diesel engine.